Planetary mixer

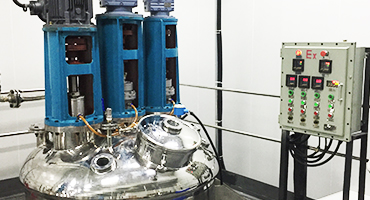

▌Product Introduction

1. Efficient and multipurpose equipment integrating mixing, kneading and dispersion;

2. It is applicable to the production processes of liquid-liquid, solid-liquid, paste-paste, powder paste and materials with large density and proportion differences from low viscosity to high viscosity (1.5 million Cps) in various industries;

3. The (trapezoidal) soft seal between the mechanical seal and the kettle body enables the materials to be operated under vacuum;

4. The kettle body can be heated by electricity, steam, water and oil circulation, and the drive shaft is equipped with a unique temperature detection device;

5. With jacket, it can realize heating or cooling;

6. The inner wall of the kettle body is finely processed by a lathe, and then automatically polished by a large polishing machine to ensure that the materials on the inner wall of the kettle body are completely hung up when the movable scraper on the planet carrier rotates;

7. The frame type agitator paddle in the kettle rotates autonomously at the same time of revolution to make the materials flow up, down and around, so as to achieve the mixing (mixing) effect in a very short time, which is more than ten times that of ordinary mixers;

8. The revolution, rotation and wall scraping agitators of the agitator in the kettle adopt frequency conversion speed regulation;

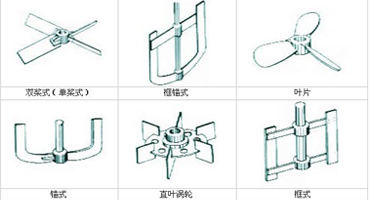

9. Extruder is optional;

10. Different mixing forms are available for different processes. customized non-standard design.

▌Technical Parameter

|

Model |

Capacity L |

Diameter mm |

Power kW |

Revolution speed rpm |

Autorotation speed rpm |

Disperser Power kW |

Disperser Speed rpm |

|

HJXJ-2 |

2 |

180 |

0.75 |

52 |

64 |

0.75 |

2900 |

|

HJXJ-5 |

5 |

240 |

1.1 |

63 |

99 |

1.1 |

2900 |

|

HJXJ-10 |

10 |

310 |

1.5 |

52 |

82 |

1.1 |

2900 |

|

HJXJ-20 |

20 |

350 |

2.2 |

62 |

95 |

1.5 |

2900 |

|

HJXJ-30 |

30 |

400 |

3 |

53 |

82 |

2.2 |

2900 |

|

HJXJ-60 |

60 |

500 |

5.5 |

50 |

80 |

11 |

2880 |

|

HJXJ-100 |

100 |

596 |

7.5 |

60 |

90 |

15 |

2880 |

|

HJXJ-200 |

200 |

750 |

15 |

52 |

83 |

22 |

2840 |

|

HJXJ-300 |

300 |

836 |

22 |

40 |

65 |

30 |

2500 |

|

HJXJ-500 |

500 |

1000 |

37 |

35 |

56 |

45 |

2240 |

|

HJXJ-1000 |

1000 |

1266 |

55 |

40 |

65 |

75 |

1440 |

▌Remarks

1. The maximum capacity is water as the reference medium;

2. High temperature, high pressure, explosion-proof, flammable, corrosive environment can be customized.