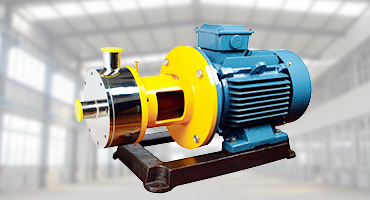

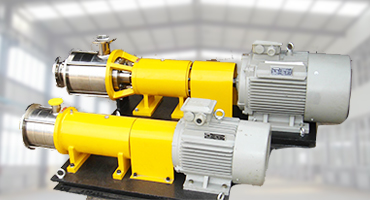

High-shear Emulsifier (Hydraulic Lifting)

▌Product Introduction

This machine is applcable for emulsification and homogenization process. The scope of application includes industrial production in various industries such as food, pharmacy, cosmetics, chemical industry, mining, paper-making, water treatment and fine chemical industry. Hydraulic lifting and pneumatic lifting are available.

▌Product Features

1. Precision matching of rotor and stator, claw type structure of working head (rotor and stator forging manufacturing);

2. Two way suction, ultra-fine dispersion and emulsification of materials, high shearing efficiency;

3. Hydraulic or pneumatic lifting mode are available;

4. Stable operation, low noise, convenient cleaning, flexible and continuous use;

5. The working temperature is less than 180 ℃;

6. Explosion proof design, safe and reliable;

7. Movable tanks are available;

8. Three clamping modes are available.

▌Technical parameter

|

Model |

Voltage kW |

Speed rpm |

Stroke mm |

Capacity L |

|

HJRH -4 |

4 |

0-2900 |

600 |

80~300 |

|

HJRH -5.5 |

5.5 |

0-2900 |

800 |

100~400 |

|

HJRH -7.5 |

7.5 |

0-2900 |

800 |

150~600 |

|

HJRH -11 |

11 |

0-2900 |

800 |

200~800 |

|

HJRH -15 |

15 |

0-2900 |

800 |

250~1000 |

|

HJRH-18.5 |

18.5 |

0-2900 |

1100 |

300~1500 |

|

HJRH -22 |

22 |

0-1440 |

1100 |

400~2000 |

|

HJRH -30 |

30 |

0-1440 |

1100 |

500~2500 |

|

HJRH -37 |

37 |

0-1440 |

1100 |

600~300 |

|

HJRH -45 |

45 |

0-960 |

1200 |

800~4000 |

▌Remarks

1. The maximum treatment capacity takes water as the reference medium;

2. High temperature, high pressure, explosion-proof, flammable and corrosive environment can be customized.

▌Applicable industries

It is widely used in food, pharmacy, cosmetics, chemical industry, mining, paper-making, water treatment and other fine chemical industries.